What Is the Difference Between IT and OT? | IT vs. OT

IT focuses on managing electronic data, while OT is centered on controlling physical processes and equipment.

IT is essential for business operations and decision-making and involves the use of computers and software to gather, store, process, share data securely. OT employs hardware and software to monitor and control industrial operations, ensuring efficiency and safety in sectors like manufacturing and energy.

What Is Information Technology (IT)?

Information Technology (IT) encompasses the tools and processes used to manage electronic data. It involves the use of computers, software, and networks to gather, store, process, and share this data securely and efficiently.

IT ensures the reliable operation of technology, facilitating timely access to accurate and secure information. The field is central to modern business operations, aiding in the quick and precise execution of tasks, analyzing data, decision-making, and the secure exchange of information.

What Is Operational Technology?

Operational Technology (OT) is the integration of hardware and software dedicated to monitoring and controlling physical devices and processes within industries such as manufacturing, energy, and telecommunications.

It employs specific technologies like Industrial Control Systems (ICS) and Supervisory Control and Data Acquisition (SCADA) to manage, monitor, and automate industrial operations in real-time. Legacy systems are common in OT, though advancements in technology are leading to more modern integrations.

OT is instrumental in enhancing the efficiency, safety, and reliability of industrial processes by providing immediate feedback and control options, minimizing downtime and maximizing productivity.

It is distinct from Information Technology (IT) as it directly interfaces with industrial equipment and processes, focusing on the physical environment and operational needs.

What Are the Differences Between IT and OT?

Purpose and Focus

IT focuses on managing and processing data, ensuring its availability, confidentiality, and integrity. It deals with the storage, retrieval, and transmission of data, ensuring that information is accessible and secure. OT is dedicated to controlling and monitoring physical processes and equipment, playing a crucial role in critical infrastructure. It ensures that machinery and processes operate effectively and safely.

Environment

IT operates in a general computing environment, managing devices like computers, servers, and smartphones. It involves standard operating systems and is centered around data-centric tasks. OT operates in industrial environments, managing specialized equipment and processes. It uses customized, often proprietary systems tailored to specific operational needs.

Security Concerns

Security risks and concerns are managed differently in IT and OT. Security in IT is primarily focused on protecting data confidentiality, ensuring that sensitive information is accessible only to authorized users. OT security, however, prioritizes the safety and availability of industrial systems and processes. The integrity and continuous operation of physical equipment are paramount in OT, given that a failure can result in significant safety and financial implications. Both IT and OT make use a range of security tools for these objectives.

What Is OT Security?

System Updates and Maintenance

IT systems are regularly updated to patch vulnerabilities and enhance performance, with established schedules for updates. OT systems, conversely, aren’t typically updated as frequently. Interruptions for updates in the OT environment can halt production, so patches are applied during specific maintenance windows to avoid disrupting ongoing operations.

Connectivity

IT is inherently connected, facilitating data exchange and communication over networks, including the internet. OT has traditionally been isolated, with systems not designed for external connectivity. However, the advent of Industrial Internet of Things (IIoT) is bridging this gap, integrating OT systems with broader networks for enhanced data analytics and operational efficiency.

Data Use and Processing

IT deals with a variety of data types, including transactional, voice, and bulky data, focusing on the broad business needs of data storage, processing, and communication. OT, in contrast, is centered around real-time data processing to monitor and control physical devices and processes. The immediacy and specificity of data use in OT are critical to ensuring operational efficiency and safety.

What Are the Similarities Between IT and OT?

Operational Efficiency

Both IT and OT seek to enhance operational efficiency within organizations. IT achieves this by ensuring data is managed, processed, and available efficiently, while OT ensures industrial processes are monitored and controlled for optimal performance. The convergence of IT and OT amplifies operational efficiency, leveraging data analytics and automation.

Advanced Technology Adoption

IT and OT are both adopting modern technologies like artificial intelligence, machine learning, and cloud computing. These technologies are enhancing data analytics, automation, and decision-making processes in both domains, leading to improved efficiency and greater innovation.

Interdisciplinary Skills

The workforce in both IT and OT is becoming more interdisciplinary. There is a growing need for professionals who understand both domains to facilitate seamless integration, manage cybersecurity effectively, and optimize the benefits derived from the convergence of IT and OT.

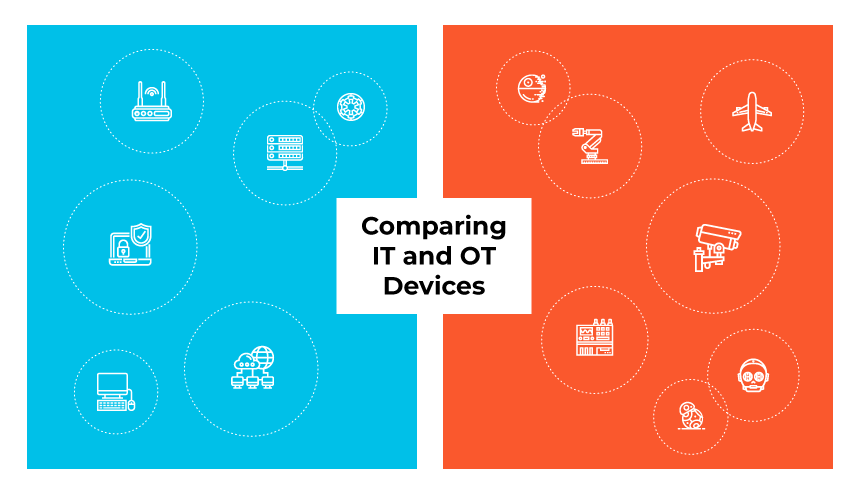

Comparing OT vs. IT Devices

IT devices are built for collecting and sending data to servers. They are straightforward, initially designed for one-way data transfer. In contrast, early OT devices, like Programmable Logic Controllers (PLCs), were focused on tasks done on-site or through PC-based programming, with limited communication capabilities.

Communication between these devices improved with the introduction of new communication protocols like EtherNet/IP, DeviceNet, and ControlNet. These protocols allowed OT devices to exchange data in real time and work together more efficiently. As a result, IT and OT started to merge, leading to better visibility and efficiency in operations.

IT devices, which are typically easier to maintain, have a shorter lifespan. They use common operating systems like Windows or Linux and are designed for general tasks like data processing and communication. OT devices, on the other hand, are made for specific control and data tasks. They are reliable and can work non-stop for many years without failing.

OT devices are also known for their durability. They are designed to withstand harsh conditions like heat, moisture, and vibration, making them suitable for industrial environments. This is in stark contrast to IT devices, which are not built to endure such challenging conditions. OT device design ensures effective integration with industrial machinery and processes.

The integration of IT and OT is often described in terms of layers. Business functions and machine data layers are becoming interconnected, in part due to advancements in Industrial Internet of Things (IIoT) technology. This integration marks a shift from isolated operations to a more connected approach where IT and OT work together.

IT and OT Convergence

The integration of Information Technology (IT) and Operational Technology (OT) is a transformative progression in the technological landscape, marking the intersection of digital and physical systems. Historically, IT and OT operated as distinct entities, each serving different functional roles within an organization.

However, this separation is changing, largely due to the advent and proliferation of technologies like the Industrial Internet of Things (IIoT) and big data analytics. The onset of Industry 4.0 is also a major driver. The siloed approach of the past is giving way to a unified, interconnected operational model where insights and data are shared across the two domains, fostering enhanced efficiency, data accuracy, and operational performance.

This convergence is facilitating a symbiotic relationship where real-time data from OT systems is fed into IT for in-depth analytics and insights. The integration of the digital and physical world offers organizations a holistic, 360-degree view of operations.

IT and OT convergence is not without its challenges, like security and technology compatibility issues. Addressing these challenges requires strategic investment in compatible technologies, comprehensive security controls and protocols, and workforce upskilling to navigate the integrated landscape effectively.

Why IT and OT Teams Must Collaborate

The collaboration between IT and OT teams is essential in the modern business environment.

Security is a primary benefit, with IT's expertise in cybersecurity proving invaluable to increasingly interconnected OT networks. IT’s experience in mitigating security risks strengthens OT’s defense mechanisms, protecting critical operational systems. The wealth of data generated from OT’s monitoring activities becomes actionable with IT’s data analytics capabilities, leading to enhanced operational efficiency.

Technical alignment achieved through the collaboration of IT and OT ensures that integrated systems are compatible, efficient, and secure. The insights and expertise of both teams contribute to a unified strategy that maximizes integration benefits. Working together is vital for capitalizing on the opportunities presented by the interconnected, data-driven industrial landscape, ensuring the organization is equipped to innovate and adapt effectively.

IT vs. OT FAQs

IoT refers to a network of interconnected devices that collect and exchange data via the internet. IIoT is a subset of IoT, specifically designed for industrial environments to improve efficiency, safety, and operational performance by connecting machines and devices. OT involves the hardware and software systems used to monitor and control industrial equipment and processes, often enhanced by IIoT to enable real-time data analytics and remote monitoring.

Though often confused, IIoT and OT are distinct; IIoT facilitates enhanced connectivity and data analytics in industrial settings, while OT encompasses the broader systems that monitor and control equipment and processes.