- 1. What Is OT?

- 2. What Is the Difference Between IT and OT?

- 3. How and Why IT and OT Are Converging

- 4. Types of IT/OT Convergence

- 5. The Role of IoT and IIoT in IT/OT Convergence

- 6. IT/OT Security Convergence

- 7. Impacts of IT/OT Convergence on ICS Security

- 8. IT/OT Convergence Benefits

- 9. IT/OT Convergence Challenges

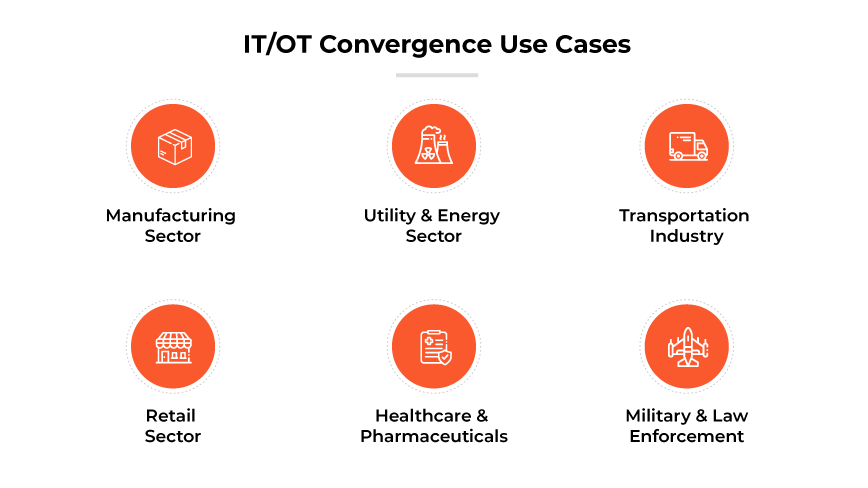

- 10. IT/OT Convergence Use Cases and Examples

- 11. IT/OT Convergence Best Practices

- 12. IT/OT Convergence FAQs

- What Is OT?

- What Is the Difference Between IT and OT?

- How and Why IT and OT Are Converging

- Types of IT/OT Convergence

- The Role of IoT and IIoT in IT/OT Convergence

- IT/OT Security Convergence

- Impacts of IT/OT Convergence on ICS Security

- IT/OT Convergence Benefits

- IT/OT Convergence Challenges

- IT/OT Convergence Use Cases and Examples

- IT/OT Convergence Best Practices

- IT/OT Convergence FAQs

What Is IT/OT Convergence?

- What Is OT?

- What Is the Difference Between IT and OT?

- How and Why IT and OT Are Converging

- Types of IT/OT Convergence

- The Role of IoT and IIoT in IT/OT Convergence

- IT/OT Security Convergence

- Impacts of IT/OT Convergence on ICS Security

- IT/OT Convergence Benefits

- IT/OT Convergence Challenges

- IT/OT Convergence Use Cases and Examples

- IT/OT Convergence Best Practices

- IT/OT Convergence FAQs

IT/OT convergence is the integration of data management systems (IT) with industrial operation systems (OT).

This integration allows for real-time data exchange, enhancing the efficiency and effectiveness of both systems. Industries benefit from improved decision-making and operational processes, grounded in accurate, timely data.

Operational Technology (OT) refers to the combination of hardware and software designed to manage, control, and oversee physical equipment and processes in sectors like manufacturing, energy, and telecommunications.

It utilizes technologies including Industrial Control Systems (ICS) and Supervisory Control and Data Acquisition (SCADA) systems to oversee, manage, and automate industrial activities in real time. Although legacy systems are still prevalent in OT, there is a noticeable shift towards more contemporary integrations due to technological advancements.

OT plays a crucial role in amplifying the efficiency, security, and dependability of industrial processes. It achieves this by offering instantaneous feedback and control mechanisms, reducing downtime and boosting output.

Distinct from Information Technology (IT), OT is characterized by its direct engagement with industrial machinery and procedures, with a concentration on tangible environments and operational necessities.

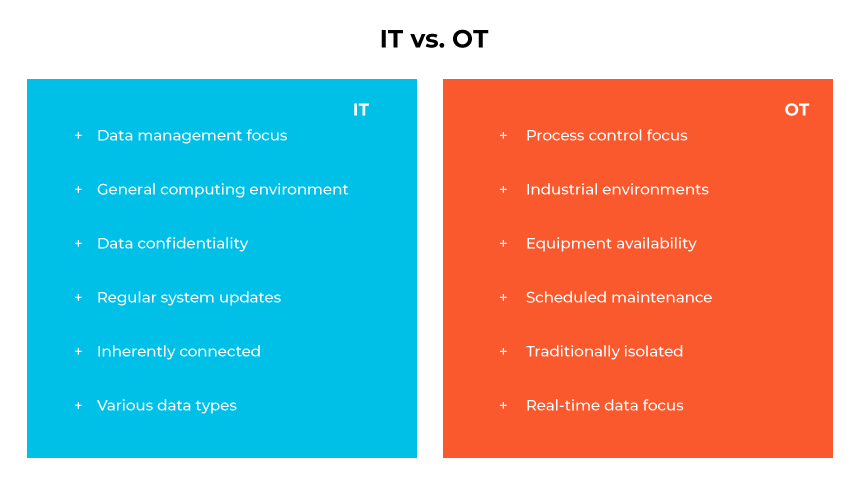

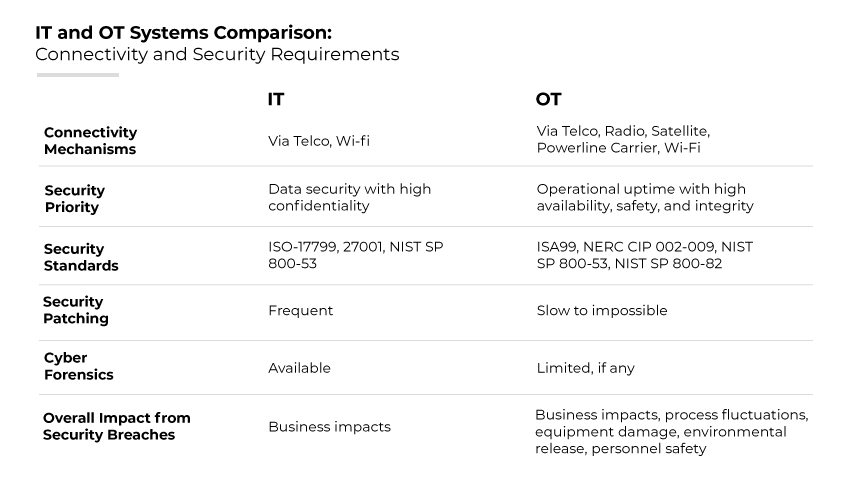

IT and OT serve distinct roles within an organization. IT is primarily concerned with managing and processing data to ensure its availability, confidentiality, and integrity. Its domain includes computers, servers, and similar devices that handle data storage, retrieval, and transmission tasks. OT, on the other hand, is tasked with controlling and monitoring physical processes and equipment, ensuring operational effectiveness and safety within industrial settings.

The environments in which IT and OT operate are markedly different. IT functions within a general computing environment and deals with standard operating systems for data-centric tasks. In contrast, OT is tailored for industrial settings, employing specialized, often proprietary systems to meet specific operational requirements.

Security considerations also vary. IT security emphasizes data confidentiality, while OT security is centered on the safety and availability of physical processes and equipment. System maintenance and updates in IT are frequent and regular, whereas OT prioritizes uninterrupted operation, scheduling updates during specific maintenance windows to avoid operational disruptions.

Connectivity and data use and processing distinguish IT and OT as well. IT is characterized by its connectivity, enabling data exchange and communication over networks. OT has traditionally been more isolated but is becoming increasingly connected due to the integration of Industrial Internet of Things (IIoT) technologies. While IT handles a diverse range of data types and focuses on broader business data needs, OT is concentrated on real-time data processing essential for monitoring and controlling industrial equipment and processes. The specific and immediate use of data in OT is crucial for maintaining operational efficiency and safety.

Traditionally, Information Technology (IT) and Operational Technology (OT) have existed in separate domains within organizations, each performing distinct functions. However, a transformation is underway, characterized by the systematic integration of these two previously isolated worlds, leading to what is known as IT/OT convergence.

This convergence is propelled by digital transformation and advances in technologies like the Internet of Things (IoT) and big data analytics. The merging of IT and OT enables a seamless flow of data between the digital and physical worlds, bridging the gap between data management systems and industrial operations. The digital information world can now not only visualize but also influence the physical operational world, leading to enhanced efficiency and innovation in business processes.

One of the core advantages of IT/OT convergence is increased efficiency. It facilitates the integration of different technologies to work as a single, cohesive system, reducing errors and enhancing workflows. This integration means that data from physical operations (OT) can be quickly analyzed and influenced by IT systems, allowing for more informed decision-making and autonomous operation which improves accuracy and uptime.

The core of IT/OT convergence is the ability to enhance the value delivered by both IT and OT systems. It fosters a level of interconnectivity that streamlines operations, fosters innovation, and introduces new services. This integration is becoming increasingly pivotal in the era of Industry 4.0 and IIoT.

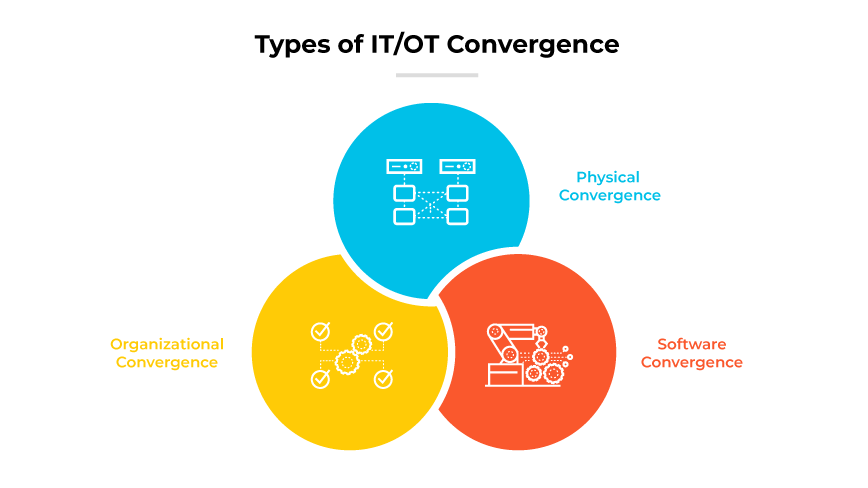

IT/OT convergence is not a monolithic concept, but a multifaceted initiative tailored to the specific organizational needs and goals.

Each type of convergence—physical, software, and organizational—addresses distinct aspects of the integration process. For example, this includes direct connection of devices, seamless data flow, and the harmonization of organizational workflows.

Physical Convergence

Physical convergence is a fundamental type of IT/OT integration where OT devices are directly connected to IT networks. It often involves modernizing or retrofitting older OT equipment to facilitate this connection. In this setup, OT devices enhanced with connectivity features can transmit data directly to IT systems for analysis and decision-making.

Software Convergence

Software convergence allows OT data to integrate with IT systems, promoting efficient information flow. The data from OT systems is collected and analyzed digitally by IT systems to improve operational efficiency. This process is crucial for real-time data processing that enhances operational control and decision-making.

Organizational Convergence

Organizational convergence involves merging the workflows of IT and OT departments to build a unified operational system. Even though IT and OT can function separately, sharing information consistently is essential. The process requires refining business operations to let IT and OT support and enhance each other's work, aiming to improve communication and teamwork.

The Role of IoT and IIoT in IT/OT Convergence

The advancement of the Internet of Things (IoT) and Industrial Internet of Things (IIoT) significantly influences IT/OT convergence.

Traditional OT devices, such as sensors, were not designed for network connectivity. This limits their function to data collection without the ability to transmit this data over a network. IoT devices are networked computing entities. They are adept at collecting, transferring, and analyzing data, and play a pivotal role in facilitating IT/OT convergence.

In the industrial context, IIoT enhances the potential of IT/OT convergence by empowering OT devices with real-time data processing capabilities. This transformation is realized through the incorporation of smart sensors on industrial equipment, enabling these devices to collect and transmit data to IoT hubs or gateways. For example, on a factory floor, enhanced sensors can gather operational data and relay it over wireless networks to back-end system applications. Applications then interpret data to inform immediate actions, such as equipment maintenance, ensuring timely interventions and minimizing downtime.

The synergy of IoT and edge computing amplifies the efficacy of IT/OT convergence in industrial settings. Edge computing allows IIoT devices to process data in real time closer to the source. This reduces the need to transmit vast amounts of data over networks to centralized locations for processing. This capability is crucial in distributed network architectures common in industrial environments. In industrial environments, immediate data insights are essential for monitoring

IT/OT Security Convergence

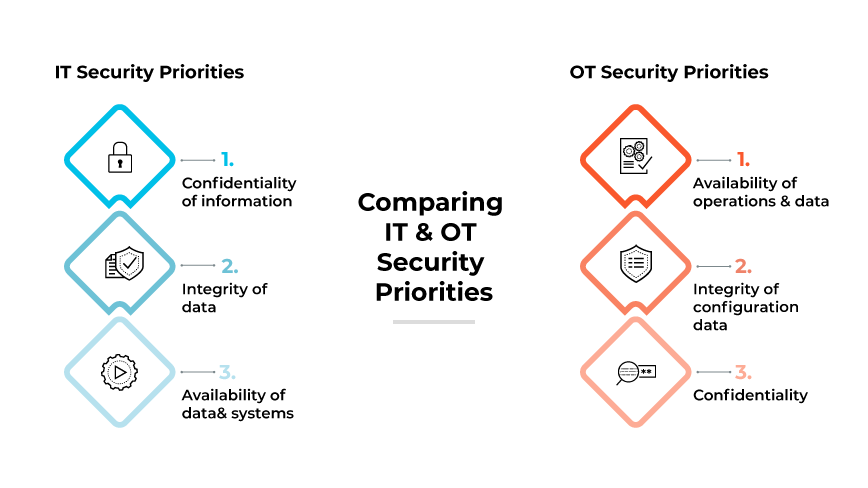

As IT and OT environments converge, there’s an adjacent convergence of IT and OT security.

Traditionally, IT security focuses on protecting data and maintaining the confidentiality, integrity, and availability of information. OT security is more concerned with ensuring the availability, integrity, and reliability of industrial processes in addition to the safety of human lives and the environment.

In the context of IT/OT convergence, security must be holistic, addressing vulnerabilities and risks inherent in both environments. This convergence involves the integration of security policies, practices, and technologies to protect the entire organization's ecosystem, covering data and industrial processes. This is important because as OT systems become more connected, they become more vulnerable to cyber threats that have traditionally targeted IT systems. A unified approach to security that covers both IT and OT environments is critical in today's interconnected, increasingly digital world.

IT/OT convergence brings about significant efficiency and data utilization advancements, but also introduces security challenges. With IT systems designed for data processing and OT focusing on the control of physical processes, their convergence creates a complex landscape. Security protocols of one may not seamlessly integrate with the other. The integration often exposes OT to cybersecurity threats, increasing the need for comprehensive security strategies that encompass both realms.

A notable challenge stems from OT systems’ enduring nature compared to the shorter lifecycle of IT infrastructures. OT systems are designed to last decades. Because of this, they often lack the built-in security features inherent in their IT counterparts. A prolonged lifecycle, coupled with proprietary designs, complicates advanced security protocol integration. The legacy nature necessitates thorough security assessments, and in some instances, comprehensive upgrades to meet converged environment security demands. Updates frequently require revisiting the concept of air gapping – the division between operational technology and IT systems that are connected to the internet.

The continuous, mission-critical nature of OT systems poses further security complexities. OT environments often cannot afford downtimes for updates or maintenance without incurring substantial operational and financial impacts. This can sometimes lead to postponed security updates, which creates vulnerabilities. The incorporation of IoT and IIoT enhances real-time data processing and analytics but also expands the attack surface for potential cyber threats.

For secure IT/OT integration, security strategies must evolve to safeguard the integrity, confidentiality, and availability of data. Organizations must balance the need for operational continuity with stringent security protocols.

Impacts of IT/OT Convergence on ICS Security

With the arrival of IIoT, every ICS sensor, instrument and device accessible over an IT/OT network is susceptible to weaponization. ICS sensors can be vulnerable to botnets used to launch targeted attacks on critical infrastructure. This includes energy grids, power plants, water and waste management systems, food processing plants, and transportation networks.

The human-machine interface (HMI) that connect operators to industrial control systems are also typically networked to various IT infrastructures. Accessibility to HMIs from internet-facing business networks poses a risk to ICS security, making HMIs susceptible to IP-based vulnerabilities. IP-based vulnerabilities can include authentication bypass, weak session management, unsecured ICS communication protocoling and insufficient control traffic encryption.

Attackers typically infiltrate ICS systems with both generic malware and malware designed specifically to target and attack critical infrastructure. These infiltrations often result in denial-of-service, or DoS, attacks that paralyze or halt industrial operations. ICS and connected IIoT devices are also high-value targets for hackers looking to collect ransoms or sabotage rival nations by gaining access to confidential data.

ICS security breaches come with vastly different consequences than standard breaches. The severe impacts of a cyberattack can include disabling a city's power grid, triggering an explosion in a nuclear plant by undermining safety systems, or rerouting sewage into an urban area's water supply.

IT/OT Convergence Benefits

The fusion of IT and OT is a practical response to the demand for increased efficiency and innovation in various industries. By aligning data analytics with core operational processes, organizations are achieving measurable improvements and overcoming complex challenges. This synergy is proving essential for cost reduction, improved decision accuracy, and adherence to regulatory standards.

Enhanced Operational Efficiency

The integration facilitates real-time data analytics and monitoring, expediting responses and decisions. It streamlines operations, delivering precise and timely insights that improve efficiency across various sectors, including manufacturing and transportation.

Cost Reduction

By incorporating predictive maintenance and automation, IT/OT convergence mitigates unexpected operational and maintenance expenses. It preemptively identifies potential issues, reducing the need for extensive repairs and downtime.

Improved Decision Making

Access to real-time, comprehensive data enables informed decisions. Clarity and information accessibility allow for adjustments that align operations with market demands and organizational goals.

Regulatory Compliance and Risk Management

IT/OT convergence enhances visibility into operations, aiding in adherence to regulatory standards. Real-time monitoring and auditing facilitate the identification and mitigation of risks, bolstering security and resilience.

Innovation and Competitiveness

IT and OT integration fosters an environment ripe for innovation. Access to diverse and comprehensive data insights unveils opportunities for developing novel solutions, strengthening competitiveness, and exploring new market horizons.

IT/OT Convergence Challenges

IT and OT integration involves navigating through a complex terrain of technological and organizational complexities. It demands a blend of varied technologies and unification of diverse professional cultures and operational standards.

Security Concerns

OT systems vulnerability during IT integration poses a significant challenge due to increased risks of data breaches and industrial espionage. The combination of legacy OT systems with IT networks exposes larger attack surfaces.

Integration Complexity

Aligning IT and OT involves overcoming issues stemming from varied communication protocols and technology standards. Ensuring seamless data collection and connectivity from diverse OT equipment while developing APIs for cloud integration is critical.

Skill Gaps

The emergence of IT/OT convergence highlights evident skill gaps. The absence of standardized training and certifications leads to inconsistencies in managing converged systems, requiring enhanced training for IT and OT personnel.

Organizational Barriers

Traditional silos separating IT and OT necessitate a shift in organizational culture. Enhanced collaboration and communication, along with integrated business policies and workflows, are essential to bridging this gap.

Equipment Compatibility

Balancing the modernization and replacement of legacy OT equipment with current IT technologies is crucial to optimizing cost and performance. Addressing incongruences ensures a streamlined operational environment.

Network Management

The management of connectivity and networks in a converged setting raises concerns about energy use, data transmission costs, and security. Organizations aim to achieve optimal performance while bolstering security protocols.

Supply Chain Obstacles

While IT/OT convergence offers enhanced visibility and control over the supply chain, it introduces challenges in data security, interoperability, and real-time management. The increased connectivity demands robust security protocols to protect sensitive supply chain data and ensure uninterrupted operations.

IT/OT Convergence Use Cases and Examples

Manufacturing Sector

In the manufacturing domain, IT/OT convergence enhances real-time data utilization, boosting efficiency. Sensors and automated systems, integrated into manufacturing processes, facilitate instantaneous data collection and analysis. This integration aids in predictive maintenance, reducing downtime, and ensuring optimal utilization of machinery, leading to cost-effective and streamlined operations.

Utility and Energy Sector

Utility and energy companies benefit from remote access to operational data enabled by IT integration. This convergence facilitates real-time monitoring and equipment control, enhancing the efficiency of inspections, damage assessments, and inventory management. IT and OT fusion contributes to optimal resource allocation and improved service delivery.

Transportation Industry

In transportation, IT/OT convergence underscores enhanced asset management. Real-time data from integrated systems guide maintenance, route optimization, and long-term planning. Enhanced visibility into asset coordination, condition, and utilization ensures timely repairs and replacements, bolstering safety and operational efficiency.

Retail Sector

The retail industry leverages IT/OT convergence for inventory and sales floor optimization. IoT devices and OT equipment, such as cameras and point-of-sale devices, provide data for real-time analysis. This integration yields insights for inventory management, cost savings, and enhanced shopper experiences, driving revenue generation.

Healthcare and Pharmaceuticals

In healthcare, IT/OT convergence enables real-time data exchange among medical devices, enhancing patient analysis and outcomes. Pharmaceutical manufacturing also benefits from this integration, ensuring quality control, streamlined production, and compliance with regulatory standards.

Military and Law Enforcement

The defense and security sectors utilize IT/OT convergence for rapid deployment and resource coordination. Enhanced insight into equipment condition and maintenance ensures operational readiness. The integration of IT data analytics with OT systems amplifies situational awareness and decision-making efficacy.

IT/OT Convergence Best Practices

Clear Communication

Transparent communication of objectives is foundational. Each stakeholder, including IT and OT teams, should understand the convergence goals. This clarity fosters alignment in strategies and operations, ensuring a unified approach in merging the two technological spheres.

Role Definition

Outlining roles and responsibilities is key to efficient collaboration. A set structure ensures each team understands its scope of work and collaboration areas. Role definition prevents overlaps and operations gaps.

Comprehensive Training

Training is instrumental in equipping both IT and OT personnel with the necessary skills and knowledge. Cross-training initiatives nurture a mutual understanding of each domain’s operational nuances. It fosters adaptability and proficiency in managing the merged technological ecosystem.

Utilization of Appropriate Tools

Strategic tool selection is pivotal for effective IT/OT convergence. Tools tailored to provide visibility and control over assets are especially essential. Functionalities must include discovery, management, configuration, and security solutions to ensure complete oversight and control.

Phased Implementation

Organizations will benefit from a structured, phased approach to implementation. Organizational, technical, and operational phases offer a systematic roadmap. An implementation roadmap encompasses collaboration, architectural design, and operation.

Network Integration Strategy

Deciding on the network integration approach is key. Options range from partitioned to fully integrated networks for IT and OT. Organizations must consider the specific requirements and constraints of the systems involved and plan accordingly.

Expertise Engagement

Involving professionals with expertise in IT/OT convergence, especially those with certifications in IoT management, will result in more informed decision making. Professional insights and experience allow for a successful and secure convergence.

- Enhanced operational efficiency

- Cost reduction

- Improved decision making

- Regulatory compliance and risk management

- Innovation and competitiveness